NEST – Exploring the Future of Buildings

NEST is the modular research and innovation building of Empa and Eawag. At NEST, new technologies, materials and systems are tested, researched, further developed and validated under real conditions. Close cooperation with partners from research, industry and the public sector ensures that innovative construction and energy technologies are put onto the market faster. NEST contributes to making the use of resources and energy more sustainable and circular.

New technologies for resource-efficient construction developed to market readiness

A digitally manufactured staircase that winds its way up to the second floor. A wafer-thin, perforated concrete ceiling that absorbs sound. Floor and wall materials made from recycled waste. The latest unit in the NEST research and innovation building at Empa is a beacon for material-saving and energy-efficient construction technologies. The STEP2 unit is officially opened.

Empowering aerial innovation for a sustainable future

Starting in early July, the latest NEST Unit, the DroneHub, has begun to take shape. Its cage, separating the research facility from the environment, is already finished. It enables unrestricted deployment of robots and drones under an open sky. Here, the Sustainability Robotics Research team wants to develop robotic applications for maintaining and repairing building structures as well as environmental sensing in wetlands and polar regions.

Subtle renovations thanks to aerogel applications in construction

For the fourth time, the Aerogel Architecture Awards were hold at NEST, honoring a total of six projects in the categories “Realized Solutions” and “Student Projects”. They all show applications of aerogel materials in architecture and construction projects that enable major savings in terms of heat loss and energy consumption through minimal intervention in the building fabric and appearance. The winners are the "Stringi-Stringi" housing complex from Italy and the Tassi Museum project from Brazil.

Selected success stories

"NEST provides the ideal environment to further develop our innovation"

As part of the HiLo project at NEST, researchers from the Chair of Architecture and Building Systems at ETH Zurich have developed an innovative adaptive solar façade that simultaneously optimizes electricity production and energy savings. Demonstrators of the façade were tested at the HiLo unit. With the founding of the ETH Zurich spin-off "Zurich Soft Robotics", the product is now to be brought to the market under the name "Solskin".

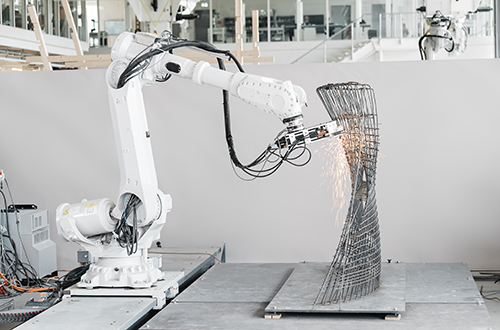

"At NEST, the MESH technology has achieved the breakthrough"

The innovative MESH technology uses robots to produce a 3D grid structure that simultaneously forms the reinforcement and formwork. This enables the production of complex, customized concrete structures. The ETH researchers used their process for the first time on the construction site during the construction of the NEST unit DFAB HOUSE showing They now reached another milestone on the way to market maturity: the founding of the ETH spin-off MESH AG.

"Thanks to our participation in the NEST project, we can now be part of the change"

In the Sprint project, partners from research and industry worked together from the very beginning to build a new NEST unit in the shortest possible time, largely with reused materials. In this interview, Maike Stroetmann from Bouygues Energies & Services talks about the challenges of the project for her and her team and the knowledge they gained in the process.